Description

The chain feeder is one of the types of feeder used in moving and transporting heavy materials, which is widely used in industries. These feeders are available in different models and capacities, and by changing their speed, the amount of output load can be adjusted and controlled. By using the stone crusher chain feeder, stones with high dimensions and weight can be easily transferred to the primary stone crusher. Chain feeders are fed uniformly and do not stop under load.

Also, these feeders are highly resistant to wear and corrosion due to their design and structure. Considering the many features and benefits of these feeders and their widespread use in many work fields, especially heavy industries, in this article we intend to introduce chain feeders to the components of these feeders, their features and applications, and important points in Let’s buy these feeders, the factors affecting the price and how to buy them online.

Introduction of chain feeder

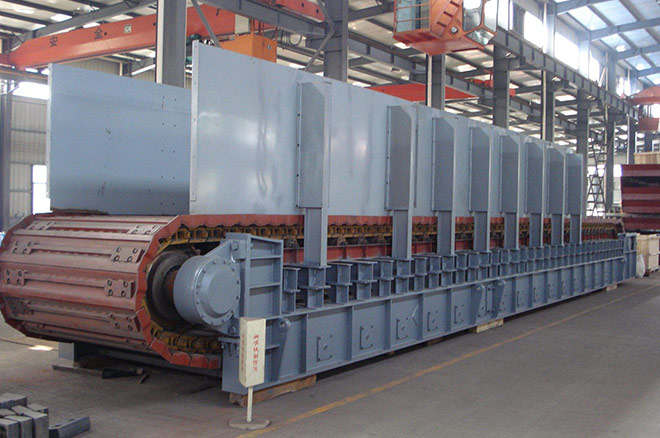

The chain feeder is a widely used model of feeders with powerful performance, in its design, metal plates are used that are placed on a chain belt. These feeders are widely used in mines and they are also used to transfer stones to the crusher. Chain guidance in these feeders is done through the drum or roller section; In this way, the conditions for the movement of the chain are provided by the rotation of the rollers and the materials are transferred through the metal plates mounted on the chain.

Chain feeders are placed in the category of heavy feeders due to their wide use in industries and heavy work fields. Using this equipment, you can carry and move large-sized and heavy materials. These feeders have a high ability to transfer materials; In this way, they will be able to easily move muddy and wet materials that have high density and adhesion. Various parts and components have been used in the design of these feeders, and the overall performance of the feeder is affected by the performance of each of these parts.

The resistant structure of the chain feeder, along with its high productivity, has made this feeder highly popular in many fields of work. Chain feeders are available in different types and models according to their dimensions, capacity and chain width, which can be used in different working conditions. Also, according to the size and type of funnel, these feeders are divided into two categories: feeders with large funnels and feeders with small funnels.

Chain feeder components

Various components and parts are used in the design of the chain feeder, the most important of which are the electric gearbox, rollers, metal plates, chassis and funnel, each of which has a special design and function. The power required to rotate the chain and finally to rotate the rollers of the machine is provided by the electric gearbox section, which is a combination of electric motor and gearbox.

Rollers are one of the important components in the design of these feeders, on which the chain tape is placed and provides the basis for their movement. The metal plates of the feeder are placed on the chain section and direct the material to the receiving device. The funnel is a part of the feeder device through which the material enters the device. Finally, all the components and parts used in the design of these feeders are mounted on a main frame called the feeder chassis.

Features and benefits of chain feeder

Chain feeders have high power and productivity due to their design and structure. These feeders have high strength and resistance against impact and erosion and will be able to move and carry heavy, wet and sticky materials. Chain feeders have the ability to adjust the speed, which can be used to control the amount of output load.

It is possible to use these equipments at high temperatures and by using them you can move materials with high temperatures. Also, these equipments have the ability to control the input flow and can be used without interruption and under heavy load. These feeders require little maintenance and spare parts will be available if needed. Other features of chain feeders include their low price and high durability.

The Conbelt website said about chain feeders as follows; Conveyor feeder is a device used to transfer materials to the conveyor belt. These units are typically used as part of an assembly line production system, although they can also be used with a variety of industrial machinery and equipment.

Chain feeder applications

Chain feeders have wide applications due to their features and capabilities. The main use of these feeders is in heavy industries, because these devices have the ability to move and carry stones with high weight and dimensions. Other uses of these feeders include their use in stone crusher workshops and cement factories. Also, this equipment can be used in chemical and electrical metallurgy industries. Another application of these feeders is in mines, where wet and sticky materials with high density can be moved easily.

Chain feeder operation

The performance and working mechanism of chain feeders is such that at first, the driving force required to move the feeder components is provided through the electromotor section. Then this force is transferred to the rollers through the gearbox section. The beginning and end rollers of the feeder provide the basis for the movement of the metal plates of the feeder, which are placed next to each other in the form of a chain strip, with their rotational movement. In this step, the materials are placed on the metal plates through the hopper part of the machine, and the materials are moved to the outlet of the machine with the movement of the plates.

Important points in buying a chain feeder

Paying attention to a series of tips and factors before buying a chain feeder will make you buy a quality device that fits your work needs. Accordingly, in this section, we are going to discuss a series of practical tips regarding the purchase of this equipment. The first point is to pay attention to the type and model of these feeders, which are usually selected based on working conditions and needs. The second point regarding the purchase of these feeders is to pay attention to their productivity capacity, which is expressed in terms of tons per hour, and it is necessary to choose it according to the work needs. Accordingly, it is better to use high-capacity feeders for heavy and high-volume work.

The next point is to pay attention to the width of the chain used in this equipment, which will have a great effect on their capacity. Feeders that use wide chains in their design have a higher yield capacity. One of the important points in buying chain feeders is paying attention to the type of material used in the construction of these feeders, which has a great effect on their durability. Of course, the quality of making feeder parts also affects the performance and efficiency of this equipment, which must be taken into account when purchasing. Finally, if you are looking for quality and durable examples of chain feeder, it is better to buy this equipment from reputable brands and companies in this field.

Chain feeder price

There are various factors that can affect the cost of chain feeders, which must be taken into consideration when purchasing this equipment. The first factor affecting the price of these feeders is their type and model, which are selected based on the needs and working conditions and are offered at different prices. The second factor that can change the price of these feeders is their capacity, which has a great impact on their work efficiency. Feeders that are supplied with high capacity are suitable for heavy working conditions and have a higher price. Another factor in this field is the width of the chain, which will affect the capacity of this equipment and cause a difference in their final price.

The feeders that use wider chains in their design have a higher capacity and have a higher price. Other factors affecting the price of chain feeders include the type of raw materials used in their construction, which has a great impact on the durability and lifespan of these equipments. Also, the feeders that are designed with high-quality components are more expensive due to their better performance and efficiency. The brand and manufacturer of the feeder is another factor that causes a difference in the final price of this equipment. Feeders that are offered by reputable and popular companies have a higher price. Of course, the role of sellers on the cost of these feeders should not be overlooked.

Online purchase of chain feeder

You can purchase chain feeders both in person and online. Nowadays, the online purchase of this equipment is very popular among buyers due to its advantages and is used more often. In the online shopping method, there is no need to go in person to the stores that supply this equipment, and this also saves time and money for the buyers. Of course, it is recommended that these equipments be purchased from reputable stores in this field, and we will introduce you to the Rehavaran Sanat Qomes store, which provides the best models of chain feeders with high quality and reasonable prices.

Reviews

There are no reviews yet.