Showing 1–3 of 21 results

The conveyor belt is a widely popular and frequently utilized tool for transporting materials and products. It is used in a wide range of industries, such as food, pharmaceutical, chemical, and agricultural. The use of conveyor belts is associated with improved safety and speed of execution in transmission systems, leading to significant enhancements in system efficiency. There is a wide selection of conveyor belts available, each designed for specific operating conditions and environments. This equipment is ideal for locations with limited space and accessibility, offering the advantage of reduced operating expenses.

This article provides a comprehensive overview of conveyor belts, covering various types and models, their components and systems, working principles, benefits, applications, maintenance and repair procedures, factors influencing price, and online purchasing options. It aims to equip readers with a thorough understanding of these essential tools used in industries for material transfer.

Introduction

Conveyor belts are widely used in various industries to efficiently transport and transfer materials and goods. Conveyor belts are an invaluable tool for transporting large volumes of materials and goods that would be impossible to move continuously or without interruption by human power. The use of conveyor belts dates back to 1892 when they were first introduced to transport coal and minerals. Since then, these belts have found applications in numerous industries.

The use of conveyor belts peaked in mines during the 1800s, a period when significant progress was made in their structure and design. The design of conveyor belts involves a sturdy belt that smoothly rotates around drums, ensuring efficient movement of materials. The dimensions of the belt and the driving force behind its rotation may vary depending on the demands and circumstances of the job. Conveyor belts have versatile applications in various industries, allowing for vertical, inclined, or horizontal use.

Types of conveyor belts

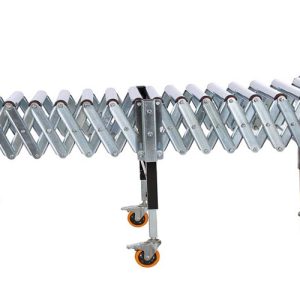

There is a wide variety of conveyor belts available, each designed for specific purposes and industries. These designs can also be customized to provide high flexibility for use in various working conditions. There are various types and models of conveyors available, including chain conveyor belts, loading conveyor belts, rotating conveyor belts, wire conveyor belts without transverse wires, gutter conveyor belts, inclined conveyor belts, gravity conveyor belts, roller conveyor belts, magnetic conveyor belts, vibrating conveyor belts, assembly conveyor belts, rolling conveyor belts, slat conveyor belts, screw conveyor belts, modular conveyor belts, bowl conveyor belts, lifting conveyor belts, accordion conveyor belts, arm conveyor belts, tow conveyor belts, curved track conveyor belts, apron conveyor belts, telescopic conveyor belts, and pulley conveyor belts.

Components and parts of a conveyor belt

The design of conveyor belts incorporates a range of components and parts, each playing a crucial role in enhancing the performance and efficiency of this equipment. These components include the frame, belt, drum, roller, gearbox, and more.

Belt

The strip or belt plays a crucial role in the design of the conveyor belt. The smooth and consistent movement of the belt on rollers creates a reliable platform for effortlessly moving and transferring materials that come into direct contact with it. There is a wide variety of belts available, with different types, dimensions, and colors, all made from various materials to suit different working conditions.

The different types of conveyor belts based on their application include PVC belts, PVG belts, rubber belts (EP), PU belts, modular belts, metal belts, tarpaulin belts, cloth belts, fireproof belts, ribbed belts, and silicone belts.

PVC belts are commonly utilized in industries such as food, pharmaceuticals, and health, while rubber belts find application in transporting minerals, cement, coal, lime, and more. In addition to their use in transporting materials such as water and oil at high temperatures, metal belts are also commonly employed for this purpose.

Drum

The conveyor belt drum is designed in two types: the driving drum and the movable drum. These drums are positioned at both ends of the conveyor belt. The design of conveyor belts incorporates various types of drums, each with its own specific purpose. These include the ball drum, idler loading drum, idler return path drum, and tension adjustment drum, among others. The drums come in various types and sizes, each designed for specific conveyor belt applications.

Roller

The roller is one of the key components of conveyor belts that greatly influence their performance in material transfer processes. This equipment’s performance in moving and transferring materials is greatly enhanced by the use of rollers in the design of conveyor belts. Additionally, the friction between its parts is significantly reduced. The rollers play a crucial role in supporting the conveyor belt and significantly contribute to enhancing the efficiency of material handling. The design of rollers varies based on the type and application of the conveyor belt, with different types and dimensions available. Additionally, the choice of materials for the rollers depends on the specific working conditions.

Gearbox motor

The gearbox motor is a crucial component in the construction of the conveyor belt, consisting of two parts: the electromotor and the gearbox. The electromotor is responsible for supplying the necessary driving force to rotate the rollers and, ultimately, the conveyor belt. The power and capacity of the gearbox are determined by the type of conveyor belt being used. Another essential component used alongside the electromotor is the gearbox. Its purpose is to effectively manage and manipulate the speed and torque of the conveyor belt. There are several types of gearboxes commonly used in the design of conveyor belts, including helical, snail, pendant, and cranial gearboxes.

Frame

The frame or body plays a crucial role in the design of conveyor belts, as it serves as the foundation for all the components and parts of the conveyor belt. The frame is designed in three models: profile, tube, and gutter, depending on the efficiency of the conveyor belt. The tube model is commonly found in conveyor belts used for transporting various materials such as coal, iron ore, gravel, sand, and lead. The profile type is commonly utilized in the design of conveyor belts for transferring granular, powder, and other similar materials due to its lower weight. The gutter type is highly effective for transporting materials over long distances, thanks to its exceptional strength.

Systems utilized in the design of conveyor belts

The design of conveyor belts involves the use of different systems, including the movable power transmission system, the steering system for regulation, the loading system, the navigation system, the unloading system, and the cleaning system. Now, let’s provide a brief introduction to each of these systems.

Portable power transmission system

The portable power transmission system consists of several components, including an electromotor, gearbox, chain and sprocket, belt, ball bearings, pulleys, and coupling. The system is in charge of efficiently transferring power from the source to the conveyor belt, resulting in the smooth movement of materials and goods.

Steering (regulation) system

The steering system, also referred to as the regulation system, consists of two components: the self-regulation system and the gravity system. These components are responsible for maintaining proper belt tension and minimizing friction.

Loading system

The loading system is an essential component in regulating and controlling the placement of materials on the conveyor belt. The system consists of a range of components, including funnels, shots, automatic pushers, and automatic loaders.

Navigation system

The navigation system is responsible for altering the direction of the conveyor belt, as its name implies. The system is comprised of a range of components, including pushers, ejectors, shock absorbers, and more.

Unloading system

The unloading system in the conveyor belt efficiently guides the load outside the device for seamless unloading. This system has been designed with a variety of components, including gutters, outlets, separators, packers, and more.

Cleaning system

The cleaning system is specifically designed to ensure the conveyor belt and rollers are kept clean, which is crucial for their reliable operation and long lifespan. The system includes slats and brushes that help to minimize repair and maintenance costs.

?How does a conveyor belt work

The conveyor belt is powered by an electromotor, which supplies the necessary torque and speed. Certainly, the torque and speed can be modified and fine-tuned by using the gearbox. The torque is transferred to the drum of the conveyor belt through the gearbox, which consists of two driving and moving rollers positioned at both ends of the conveyor belt. The driving roller rotates to provide the necessary force for moving the belt that covers the rollers in a continuous strip.

The conveyor belt smoothly and efficiently transports materials and goods from the input section to the output section of the machine. The use of ball bearings in rollers greatly enhances their performance and minimizes noise pollution. Furthermore, the rollers enhance the belt’s movement by rotating along the path. The controller system is utilized in certain conveyor belts to enhance performance and boost efficiency.

Advantages of conveyor belt

Conveyor belts offer numerous advantages thanks to their well-designed and versatile nature. One notable benefit is their ability to significantly increase the speed of material transfer. The use of conveyor belts allows for the seamless transfer of a substantial amount of materials and goods, resulting in improved efficiency during the execution process. In addition, conveyor belts have the advantage of being environmentally friendly and quiet, thanks to their design. They also take up minimal space.

The energy consumption of conveyor belts is low, making them suitable for moving materials of various structures in any direction – be it horizontal, vertical, or inclined. When working with conveyor belts to move and transfer materials, there is no need to exert excessive force. This issue holds significance from two different perspectives. The first point to consider is the cost-saving benefits of reducing the need for manpower in work processes. Additionally, it is crucial to address the issue of minimizing human error in the executive process and enhancing system safety for employees.

Applications of conveyor belts

Conveyor belts find applications in a wide range of industries, including airports, stores, shopping centers, bakeries, post offices, and more, thanks to their numerous features and benefits. In addition, these devices have a significant impact on a variety of industries and are extensively utilized in sectors such as food, pharmaceuticals, healthcare, chemicals, agriculture, and more. Conveyor belts have proven to be incredibly useful in mines, as they efficiently transport and transfer minerals from the mining workshop to the processing plant.

Conveyor belts play a crucial role in the production and assembly lines of factories, making them incredibly valuable. There are various types of factories, including cement factories, steel factories, asphalt factories, and more. Furthermore, conveyor belts have applications in both material distribution and storage.

Conveyor belt repair and maintenance

The performance and lifespan of conveyor belts can be greatly improved through timely repair and maintenance, ensuring continuous and uninterrupted operation. Before each use, it is essential to examine the belt’s condition and, if needed, make the necessary repairs or replacements. The same principle can be extended to other parts of the conveyor belt, with the rollers being a prime example.

It is important to ensure that the conveyor belt is accurately adjusted and promptly address any deviations that may be detected. The timely lubrication of conveyor belts is crucial for ensuring optimal performance and durability of this equipment. It is important to ensure that these devices are shielded from moisture and direct light and maintained at an appropriate temperature. It is crucial to pay close attention to the movement of the belt in the conveyor belt. Therefore, it is advisable to prevent excessive tension on the belt while it is in operation.

?How to choose a conveyor belt

Before selecting and purchasing a conveyor belt, it is crucial to consider a range of factors and points to ensure the acquisition of a reliable and top-notch device. Additionally, you may find the article guide to purchasing a conveyor belt to be a valuable resource for further information. When selecting a conveyor belt, it is crucial to consider the type of materials being transported and the working conditions. This will help determine the most suitable model with a specific design and application. The various types and models of conveyor belts, including chain, belt, and telescopic, are designed and supplied to accommodate a range of working conditions. The technical specifications of the conveyor belt, including length, width, power, and capacity, should be carefully chosen to suit the working conditions. When it comes to challenging and demanding operations, opting for robust conveyor belts with larger dimensions and higher capacities is the way to go.

The next point to consider is the type of controlling system, which typically falls into three categories: manual, automatic, and semi-automatic. Considering the type and direction of movement of the conveyor belt is an important factor to consider.

Conveyor belts are versatile tools that can efficiently transport materials in various directions, including horizontally, inclined, and even vertically. It is crucial to consider the brand of the manufacturer when evaluating the efficiency and durability of a conveyor belt.

Price of conveyor belt

The price of conveyor belts can be influenced by various factors, such as the type and model of the device, its dimensions, applications, power and capacity, controlling system, belt’s strength, material used in the design, part quality, rubber coating, manufacturer brand, and sellers. Every model of the conveyor belt is priced according to its unique design and applications. In addition, devices with larger dimensions, such as longer and wider belts, tend to be more costly.

The price of the conveyor belt increases due to its enhanced tensile strength and exceptional resistance to heat and moisture. Furthermore, the cost of automatic conveyor belts is higher in comparison to manual models because of their simplified operation. Using high-quality parts in the design of conveyor belts enhances their efficiency and durability, which in turn affects their price. In addition, conveyor belts from established and respected brands come with a higher price tag due to their superior performance and long-lasting quality.

Online purchase of conveyor belt

Conveyor belts are available for purchase through various channels, including both physical stores and online platforms. In today’s digital age, the convenience and benefits of online shopping have made it a preferred method over traditional in-person purchases. Online buying eliminates the need to visit the store in person and saves you time and money. You can conveniently browse and purchase various models of conveyor belts, complete with their specifications and prices, on sales websites that are available 24/7. Rahavaran Sanat Qomes is a highly regarded store that offers a wide range of conveyor belt models. This center offers a wide selection of the latest conveyor models, ensuring both high quality and reasonable prices.