Conveyor belt and information about the different stages of design of loading conveyor belt and conveyor belt in this article is provided from the website of Rahavaran Sanat Qomes company, which we will discuss separately below.

Useful information that can help in choosing the right conveyor belt purchase are:

Select device speed

Used conveyor belt speed variations

Design considerations

Energy consumption

displacement efficiency

Identifying the resistance of the rollers

required confidence coefficients

Select Idler Roller

Transfer stations

Conveyor belt speed selection system

First of all, one of the most important items in the conveyor belt buying guide is system design, selection of belt speed, capacity and type of material. Optimal design is based on static specifications. In this plan, the purchase of mining conveyor belt is considered as a rigid and inelastic object. Based on this, the properties of the steady state and the characteristics and dimensions of the strip can be defined. Also, the generated tensions, energy consumption and other factors can be calculated according to the applied load.

It should be kept in mind that the optimal design cannot be done with one calculation, but it can be achieved by repetition.In a good design, the starting and stopping stages should be well considered, and parameters such as the control algorithm, the dimensions of the tape and its components such as drivers, flywheels and brakes are dynamically calculated. .Brakes play a significant role in neutralizing the forces resulting from the torque that can be installed in the system.

In this design, due to the 2% slope from the origin to the destination, electromechanical brakes should be used. If the gearboxes used in the system have the ability to be locked after the system is turned off. Side brakes are no longer needed. Failure to use brakes in the system causes the reverse force to be applied to the tensioner and belt. In this design, the strip is considered a three-dimensional viscoelastic object.

Also, mechanical theories should be used to calculate the movement time of components and its relationship with other factors. In this theory, the belt is divided into a series of finite elements, which helps to better understand the characteristics of the belt and its selection. It is also possible to estimate stresses and energy loss with dynamic analysis.

Recommended product: helical gearboxes

Choosing the speed of the conveyor:

For the lowest speed of the belt, the width of the belt should be about 60 to 10 cm. Transmission capacity. Belt tension and speed can be selected according to each other.The speed of the device is considered by inverters, whose power is determined according to the type of drive motors, which has the ability to change the speed of the belt, and also has a direct relationship with power and capacity.

According to the information given about the material transfer capacity per year, the speed of the desired shopping conveyor is considered to be about 3 meters per second, and if capacity increase items are seen before designing, it can be increased up to 5 meters per second. .Considering the length of the system, it takes about 15 to 30 minutes to start the system, which prevents sudden stress on the belts and tensioners.

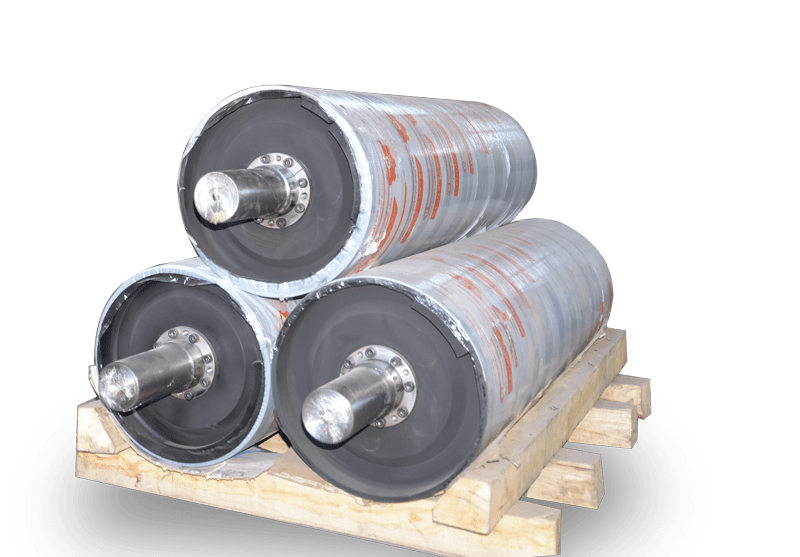

Pullers are a set consisting of drums with a defined diameter that cause more friction with the belt, which together cause the belt to move at the time of starting.However, the choice of conveyor belt speed depends on a series of practical considerations:

The first feature of the speed of the used or new conveyor belt:

The first feature (trough ability) is the tensile strength of the belt. In fact, there is no relationship between the strength of the belt, which is also dependent on its length, and the lift, a suitable combination of width and strength of the belt should be chosen to provide proper trough ability. Otherwise, the belt does not move properly and this has an unacceptable effect on the behavior of the belt, especially when the speed is high.

In order to increase the friction of the belt and pulling drums, weights of 20 kg are installed in the vertical position every 2 km. Also, due to the 2% increase in the length of the belt after several start stages, this prevents the belt from loosening in the long term. In this system, the belt type is 1200 ST, its width is 100 cm and its thickness is 18 mm.

In this system, due to the slope of 2%, the distance between each tensioner can be 1 kilometer, and if the distance is less than this value, belts with lower tensile force can be used. With this, the cost of the belt will be reduced to some extent. But due to the high number of killers and the complexity of the system, more energy and time is spent on its maintenance.Therefore, it is recommended to keep the distance between the conductors as high as possible.

Recommended product: electro motor 3 phase

Normally, belt manufacturers expect a strong performance. If approximately 60% of the width of the belt is occupied, it will make contact with the rollers, and if it is 90%, it will touch completely.

The second feature that affects the speed of the conveyor:

The second characteristic is the speed of the air relative to the speed of movement of materials.If the relative speed of the air exceeds a certain limit, it causes dust.

Of course, the range of air speed depends on the environmental conditions and the properties of the moving materials.If the conveyor belt is covered with special covers, it can be ignored.

Of course, it should be mentioned that these covers increase the lifespan of second-hand conveyor parts.

The third feature of the relationship between conveyor speed and noise pollution

The third feature is the noise pollution created by the conveyor belt. The amount of noise usually increases with increasing speed. In some areas, there are also limits for the amount of noise pollution. Of course, it should be noted that the amount of noise depends on the foundation and support parts.

Conveyor speed changes:

The wasted energy of the chain conveyor belt is changed by changing the speed, the flow speed of the material itself can be used. With this, you can save some energy. If the treadmill conveyor is working with the highest tonnage. The maximum speed should also be used if the belt filling operation is carried out continuously. We will have the highest efficiency, which in this case also reduces wasted energy.

If the feeding speed of the conveyor is variable with the speed of material flow, it brings benefits:

Less space of the belt is placed under the load

Less noise pollution

Improving belt behavior and better alignment

Absence of bulges in the belt

Reducing the tension in the belt

Recommended product: electric motors single phase

Some disadvantages:

Investment cost for towbars and brakes

Changes in energy consumption with changes in the speed required by the control system for individual conveyors

High and constant initial stress

Design considerations:

The amount of space occupied by the load on a 100 cm wide belt is about 0.7 belt width per square meter. According to the density of limestone, the vertical weight of the hair on the belt should be about 150 kg per meter. The speed of material transfer in normal mode should be considered 3 meters per second. The capacity of the system is obtained by multiplying the speed by the value of the vertical weight of the material on the belt, which is a number equal to 1620 tons per hour.

Energy consumption

Rubber conveyor belt customers may have a specific energy consumption in mind. For long distances, some energy is spent to overcome the resistance of the tape belts. This resistance between the conveyor roller and the belt is caused by viscoelastic properties. Also, resistance due to inertia in the wall and material acceleration are also effective. The pulling force is calculated as the sum of the total inertial resistances and the lifting force of the material.

The resistive force including hyster-zeiss losses are considered as viscous resistance. Only calculating the maximum energy for the killer based on resistances is not enough, the energy consumption in different states and systems should be compared.

Recommended product: conveyor belt fasteners

displacement efficiency

There are various methods that calculate displacement efficiency.The first and best method is to calculate resisting force factors such as the DIN F factor. The second method is to calculate the cost of moving in different situations, this practice is generally used in management cases. The disadvantage of this method is that it does not show the efficiency of the system in a real and direct way.

The third method of comparison is displacement loss factor. This factor is the ratio between the tensile force required to overcome the resistances and displacement. The displacement work is obtained from the product of the total load moved by the average speed. The advantage of using this method is that it considers the loss in different proportions. The disadvantage of this method is that the displacement loss factor depends on the amount of material moved. So it cannot be used for an empty conveyor belt.

The cisco-eaglewebsite wrote about the proper height of the conveyors; Set the conveyor at medium height (30 inches as mentioned). This is fine most of the time for most people. Set the conveyor height to the 75th percentile height. Short workers will often have loads somewhere between knuckle and elbow height.

Examples of displacement loss factors:

Continuous displacement:

Displacement of aqueous material is about 0.01 tube

Vibrating feeders between 0.1 and 1

Conveyor belt between 0.01 and 01

Pneumatic conveyors 10

Discontinuous displacement:

Ship 0.001 to 0.01

Train 0,1

Truck between 0.1 and 0.5

The displacement factor is introduced as a number, the lower the method, the better mechanically, but costs are not considered. Identifying the resistance of the rollers for high energy consumption systems is determined based on the work done to overcome the resistance of the rollers. The idler roller base is made of relatively hard materials such as aluminum or steel, while the conveyor belt covers are made of softer materials such as plastic or PVC.

Therefore, the rollers will tooth the underside of the belt as the belt moves over the idler roller, due to the weight of the belt and the bulk of the belt’s lining material. The recovery of compressed parts on the undercoating of the belt takes time due to its viscoelastic properties. A time delay in the improvement of the undercoating of the belt leads to an asymmetric distribution of pressure between the roll belts.

Recommended product: Self-Aligning Turning Roller

The magnitude of this force depends on the viscoelastic properties of the cover material, the radius of the idler roll, the vertical force due to the weight of the belt and bulk solids and the radius of curvature of the belt in the vertical curve. If the vertical load in the belt decreases by a factor of 2, then the resistance of the roller decreases by a factor of (32 2.52). The volume of the load decreases with the increase in the speed of the belt assuming a constant capacity, so the resistance of the roller decreases more than the ratio of the increase in the speed of the belt. finds

Secondly, the resistance of the rollers depends on the size of the idler rollers. In general, the diameter of the idler rollers increases with the increase of the conveyor speed to increase the life of the roller, therefore, the resistance of the rollers decreases with the increase of the speed. Thirdly, the resistance of the rollers also depends on the viscoelastic properties of the belt coating.These properties depend on the variable rate of shape, which in turn depends on material load, belt and belt speed, but generally their ratio is small.

Fourth, the resistance of the rollers also depends on the thickness of the belt. It should be noted that the resistance of the rollers, although it is important, but the resistance is not only dependent on the speed, it is also dependent on other factors such as the general load entered, which is directly dependent on the speed of the conveyor. Another type of resistance is caused by particle acceleration, which increases with increasing speed.

Required confidence coefficients:

By using different standards, generally 2 types of confidence coefficients are defined:

1- Based on steady state tensions

2. Based on non-stationary stresses

But in general, the confidence factor is calculated based on the steady state stresses based on the following six cases:

1- Stresses in the state of rest and movement (bar hollowness, summer, winter)

2- belt tensions caused by additional resistances and changes in forms caused by horizontal and vertical curves in the pulley and support of the conveyor system

3- Functional characteristics of the system such as working hours and working days as well as distance

4- When every service and maintenance of the system

5- connecting the belts together and fatigue profile of the belt

6- Connection of storage and guidance kits

To determine the reliability coefficient of tires, all the above six factors must be considered.

In some standards, only the first 3 cases are considered, if we consider their coefficients in the order of RO, R2, R1, our desired reliability coefficient is as follows:

SF=1/1-(R0+R1+R2)

which usually R0>0.665, R1>0.15, R2>0.06

In this case, usually SF>8

Selection of Idler (roller):

The most important criterion for choosing an idler for a high speed conveyor is the diameter of the idler. In general, it can be said that as the speed increases, the diameter of the idler also increases. The reasons for this are: 1. idler bearing 10 is commonly used at low rotation speeds.

Idler diameter significantly affects its performance. On the other hand, temperature is also a factor that limits the speed for it. If any slip occurs between the belt and the idler shell, the diameter of the idler must be such as to control it.Slippage occurs if the idler rotation circuit and the belt direction are not in the same line, that is, the belt does not follow a straight path due to the horizontal curvatures.

The resistive torque and resistance created by the idler decreases with increasing diameter.The only problem with increasing the diameter of the idler is the increase in cost.Another point is that the life of the ldler decreases with the increase in the speed of the belt. Also, if the correct diameter is not selected, increasing the speed will cause the idler to vibrate.

Recommended product: Ribbed conveyor belt

Transfer stations

A very important point in the design of conveyors is the design of proper feeding and basic discharge of the tape. The main problem in high-speed conveyors is the proper placement of materials with the appropriate speed and correct direction on the tape, which causes some parts of the tape to remain empty.

There are two ways to solve this problem:

1- The use of an accelerator on the conveyor is to coordinate its speed with the loading of materials.

2- Using a system for proper speeding of the materials to be placed on the tape so that the minimum difference in speed and direction between the materials can be created.

But today there are methods such as DEM (Discrete Element Mod) that can be used to model the flow of material loading on the conveyor belt. This modeling helps designers to determine the required speed and the force that the material exerts on the belt. should be estimated according to the speed of the conveyor belt.

For this purpose, tanks or suitable places for emptying should be installed, and measures should be taken to spread dust if needed. The conveyor device should be placed on the support along the way.In order to prevent vibration, these supports must be fixed along the route with reinforced concrete, which is at a distance of 1 cubic meter of reinforced concrete, which is determined after determining the distance to the floor.Also, plates are provided for the support to be placed on it.Also, the foundation with a higher volume should be predicted.

Frequently Asked Questions Conveyor Buying Guide

What type of conveyor is best for moving cargo?

First of all, it should be noted that conveyors are available in different types and models, such as belt conveyors, chain conveyors, disc conveyors, roller conveyors, etc., which should be selected according to the needs and working conditions. For example, belt conveyors are more suitable for moving light loads with specific dimensions, and disk conveyors can be used to transfer powder and granular materials. In addition to the type and model of the conveyor belt, attention should be paid to other specifications of these devices, including their capacity and speed.

What are the proper transmission lines for working with a conveyor belt?

Conveyors can be used horizontally, vertically and inclined depending on the conditions and working space. Generally, these devices are used in the form of horizontal and inclined transmission lines, which can also be used in the form of vertical transmission lines depending on the working conditions. For this, it is enough to use a combination of horizontal conveyors on both sides and inclined ones in the middle.

What is the proper efficiency of working with a conveyor belt?

The efficiency of the conveyor depends on various factors, the most important of which is the capacity of the conveyor. In the design of these devices, different electric motors are used, each of which has a certain power and strength, which must be taken into account when choosing a conveyor belt.

What is the reason for choosing a roller conveyor?

Roller conveyors have the ability to adjust the height and slope, and they can be used to move and transfer packaged goods. Other features of these conveyors include their ergonomic design and washable features. In addition, roller conveyors are easy to maintain and require little maintenance and service.

What are the reasons for choosing a chain conveyor?

Using chain conveyors, heavy loads such as pallets, which cannot be moved by roller belts, can be easily moved. In addition, these devices can be used to move and transfer light materials that have a softer surface.

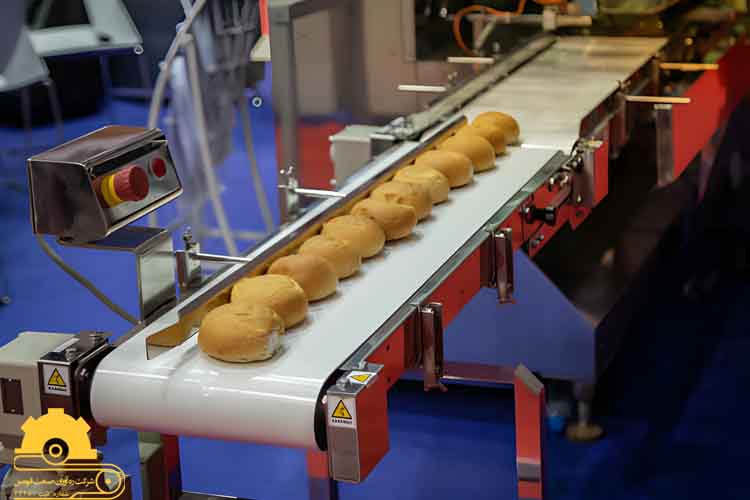

Which conveyor belt is suitable for working in the food industry?

In the field of food industry, where hygiene and cleaning of equipment is of great importance, belt conveyors that use PVC, PU, etc., are widely used in the design of their belts. This type of conveyors can be used in different parts of this field of work according to their dimensions and capacity.

The price of the conveyor depends on what factors?

Among the factors influencing the price of the conveyor belt are the model of the device, the type of belt used in its design, the capacity of the conveyor belt, the type of rollers and their number, the type of electric motor and gearbox used in its design, the quality of the conveyor parts and The brand manufacturer pointed out.